The aluminum can market has been on a steady rise for the past few years, with no signs of slowing down. The increasing demand for sustainable packaging solutions has led to a surge in the use of aluminum cans, particularly in the food and beverage industry. With the rise in the popularity of craft beers and the shift towards health-conscious drinks, the market for aluminum cans is expected to grow even further. But what does the future hold for this industry? Will the demand for aluminum cans continue to rise, or will it plateau? In this article, we will explore the aluminum can market forecast and what it means for the future of this industry. So, buckle up and get ready to find out what the future holds for the aluminum can market.

It is difficult to predict exactly what the future holds for the aluminum can market, as it is influenced by a variety of factors such as changes in consumer behavior, technological advancements, and fluctuations in global economic conditions. However, it is likely that the demand for aluminum cans will continue to grow, as they are a convenient and environmentally friendly packaging option. Additionally, the increasing popularity of e-commerce and online shopping is likely to drive growth in the market, as more products are sold in aluminum cans. However, the market may also be impacted by changes in recycling regulations and policies, as well as by the development of new packaging materials and technologies.

Aluminum cans: a growing trend in packaging

The rise of sustainable packaging

In recent years, there has been a growing trend towards sustainable packaging in the aluminum can market. Consumers are becoming increasingly aware of the environmental impact of their purchasing decisions and are demanding more eco-friendly options. This has led to a shift towards packaging made from recyclable materials, such as aluminum.

Aluminum is a highly recyclable material that can be used repeatedly without losing its structural integrity. This makes it an attractive option for manufacturers looking to reduce their environmental footprint. Additionally, aluminum cans are lightweight and durable, which makes them ideal for transporting and storing a variety of products, from beverages to personal care items.

As consumers become more environmentally conscious, the demand for sustainable packaging is likely to continue to grow. This presents an opportunity for the aluminum can market to expand and become a more significant player in the packaging industry. Manufacturers who are able to meet this demand by offering innovative and sustainable aluminum packaging solutions are likely to see increased sales and brand loyalty.

However, it is important to note that the aluminum can market will need to continue to innovate and improve its recycling processes in order to meet the growing demand for sustainable packaging. This will require investment in new technologies and infrastructure, as well as collaboration between manufacturers, recyclers, and governments.

Overall, the rise of sustainable packaging presents both challenges and opportunities for the aluminum can market. By embracing innovation and sustainability, manufacturers can position themselves for long-term success and meet the changing needs of environmentally conscious consumers.

The convenience and versatility of aluminum cans

Aluminum cans have become increasingly popular in recent years due to their convenience and versatility. Some of the reasons why aluminum cans are gaining popularity in the packaging industry include:

- Durability: Aluminum cans are highly durable and can withstand a wide range of temperatures, making them ideal for packaging products that require protection from extreme conditions.

- Sustainability: Aluminum cans are one of the most recyclable packaging materials available, and they can be recycled multiple times without losing their structural integrity. This makes them an environmentally friendly option for packaging products.

- Versatility: Aluminum cans can be used to package a wide range of products, from beverages to personal care products. They are also available in a variety of sizes, making them suitable for different packaging needs.

- Barrier properties: Aluminum cans offer a high level of protection against light, oxygen, and other gases, making them ideal for packaging products that require protection from external factors.

- Stackability: Aluminum cans are stackable, which makes them an efficient and space-saving option for storage and transportation.

Overall, the convenience and versatility of aluminum cans make them an attractive option for packaging products in a wide range of industries. As consumers become increasingly concerned about sustainability and the environment, the demand for aluminum cans is likely to continue to grow in the future.

Market trends impacting the aluminum can industry

Increasing demand for recyclable packaging

The aluminum can market is experiencing a significant shift in consumer preferences, with an increasing demand for recyclable packaging. This trend is being driven by several factors, including growing environmental concerns and the need for sustainable packaging solutions.

Consumers are becoming more aware of the environmental impact of their purchasing decisions, and there is a growing demand for products that are eco-friendly and sustainable. This has led to an increased interest in recyclable packaging, which can be easily reused and repurposed. Aluminum cans are a popular choice for packaging beverages due to their durability, versatility, and recyclability.

Moreover, governments and regulatory bodies are also playing a role in driving the demand for recyclable packaging. Many countries have implemented regulations and policies aimed at reducing waste and promoting sustainable packaging practices. For example, some countries have implemented deposit return schemes for beverage containers, which incentivize consumers to recycle their cans and bottles.

As a result of these factors, the demand for recyclable packaging is expected to continue to grow in the coming years. This presents a significant opportunity for the aluminum can industry, as more and more companies look to switch to sustainable packaging solutions. However, it also means that the industry must continue to innovate and improve its recycling processes to meet the growing demand for recycled aluminum.

Growing preference for single-serve packaging

As consumers lead increasingly busy lives, there is a growing preference for single-serve packaging options. This trend is particularly evident in the beverage industry, where convenience and portability are highly valued. Single-serve packaging offers several advantages, including reduced packaging waste, easier storage, and more convenient consumption.

In response to this trend, many beverage companies have transitioned to single-serve packaging options, including aluminum cans. Aluminum cans are a popular choice for single-serve packaging due to their durability, portability, and recyclability. As a result, the demand for aluminum cans is expected to continue to grow in the coming years.

Furthermore, the rise of e-commerce and online retail has also contributed to the growth of single-serve packaging. With more people shopping online, there is a greater need for packaging that is designed for individual use. Aluminum cans are well-suited for this purpose, as they can be easily shipped and stored without being crushed or damaged.

Overall, the growing preference for single-serve packaging is a significant trend that is likely to have a positive impact on the aluminum can market in the coming years. As consumers continue to prioritize convenience and sustainability, it is likely that the demand for aluminum cans will continue to increase.

Competition from alternative packaging materials

As the demand for sustainable and eco-friendly packaging solutions continues to rise, the aluminum can market is facing increasing competition from alternative packaging materials. Some of the key alternatives that are gaining traction in the market include:

- Glass bottles: Glass bottles have long been a popular alternative to aluminum cans, particularly for beverages such as juice, soda, and beer. They offer several advantages over aluminum cans, including the ability to be recycled indefinitely and the perception of being more premium and high-end. However, glass bottles are also heavier and more fragile than aluminum cans, which can increase transportation costs and pose logistical challenges.

- Plastic bottles: Plastic bottles have become a popular alternative to aluminum cans in recent years, particularly for sports drinks and water. They offer several advantages over aluminum cans, including lower production costs, greater flexibility in terms of shape and size, and the ability to be made from recycled materials. However, plastic bottles are also less durable than aluminum cans and can degrade more quickly in the environment, leading to increased pollution and waste.

- Cartons: Cartons made from materials such as paperboard and polyethylene have also become a popular alternative to aluminum cans in recent years, particularly for packaging fruit juices and dairy products. They offer several advantages over aluminum cans, including greater insulation and protection against light and oxygen, as well as the ability to be recycled. However, cartons are also less durable than aluminum cans and can be more difficult to transport and store.

Overall, the aluminum can market is facing increasing competition from alternative packaging materials, particularly from glass bottles and plastic bottles. While aluminum cans offer several advantages over these alternatives, such as durability and recyclability, they also face challenges in terms of cost and logistics. As the demand for sustainable and eco-friendly packaging solutions continues to grow, it will be important for the aluminum can industry to innovate and adapt in order to remain competitive and meet the changing needs of consumers and businesses.

Factors driving growth in the aluminum can market

Technological advancements in production processes

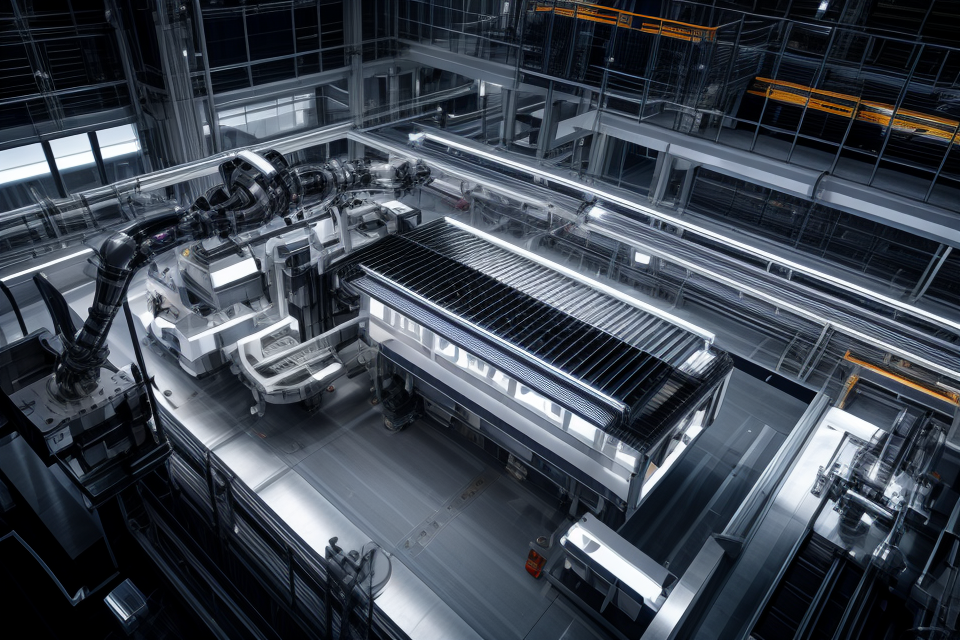

Advancements in Extrusion Technology

- Improved efficiency and precision in the production process

- Enhanced capabilities for manufacturing complex shapes and designs

- Increased production speed and reduced energy consumption

Integration of Robotics and Automation

- Reduced labor costs and increased safety

- Enhanced accuracy and consistency in the production process

- Increased flexibility in manufacturing processes

Development of Lightweight Alloys

- Reduced material usage and weight in aluminum cans

- Increased sustainability and environmental friendliness

- Potential cost savings for manufacturers and consumers

Implementation of IoT and Smart Manufacturing

- Real-time monitoring and optimization of production processes

- Enhanced traceability and quality control

- Increased efficiency and productivity in manufacturing

Overall, these technological advancements in production processes are expected to drive growth in the aluminum can market by increasing efficiency, reducing costs, and enhancing sustainability.

Growing demand for packaged beverages

As the global population continues to grow and urbanize, there is an increasing demand for packaged beverages that are convenient, portable, and easy to consume. With the rise of on-the-go lifestyles and the growth of e-commerce, the demand for packaged beverages is expected to continue to increase in the coming years. This presents a significant opportunity for the aluminum can market, as aluminum cans are lightweight, durable, and can be easily shipped and stored. Additionally, aluminum cans are also a popular choice for beverage manufacturers due to their ability to protect the taste and quality of the contents, and their recyclability. Overall, the growing demand for packaged beverages is expected to drive growth in the aluminum can market in the coming years.

Increased use of aluminum cans in food and household products

As consumers become more health-conscious and environmentally aware, the demand for aluminum cans in the food and household products industry is on the rise. Here are some of the key factors driving this trend:

- Sustainability: Aluminum cans are a more sustainable option compared to plastic bottles and glass containers. They are recyclable, lightweight, and durable, making them an attractive choice for both consumers and manufacturers. In fact, aluminum cans are the most commonly recycled beverage container in the world.

- Convenience: Aluminum cans are convenient to use and transport. They are portable, easy to open, and can be stacked for efficient storage. This makes them ideal for on-the-go consumption and outdoor activities.

- Shelf life: Aluminum cans have a longer shelf life than other packaging materials. They protect contents from light, air, and moisture, which helps maintain the quality and freshness of the products inside. This is particularly important for perishable goods like juices, soups, and dairy products.

- Innovation: Manufacturers are constantly developing new technologies to improve the performance and design of aluminum cans. For example, some companies are experimenting with aluminum bottles that are both lightweight and strong, and have unique shapes and designs that appeal to consumers.

- Health benefits: Aluminum cans are an excellent choice for packaging food and beverages because they do not leach harmful chemicals into the contents. This makes them a safer option for consumers who are concerned about the safety of the products they consume.

Overall, the increased use of aluminum cans in food and household products is driven by a combination of factors, including sustainability, convenience, shelf life, innovation, and health benefits. As the market continues to grow, it is likely that we will see even more innovation and development in the use of aluminum cans.

Challenges facing the aluminum can industry

Environmental concerns and recycling infrastructure

As the demand for aluminum cans continues to rise, the industry faces several challenges that could impact its future growth. One of the primary concerns is the environmental impact of aluminum can production and disposal. The manufacturing process of aluminum cans requires a significant amount of energy and natural resources, which can contribute to greenhouse gas emissions and other environmental issues. Additionally, the disposal of aluminum cans presents a challenge, as many are not properly recycled and end up in landfills or other environments.

Recycling infrastructure is another key challenge facing the aluminum can industry. While aluminum cans are highly recyclable, the process of collecting, sorting, and processing them requires significant investment in infrastructure and technology. Many countries have implemented recycling programs and initiatives to encourage the proper disposal and recycling of aluminum cans, but more work is needed to ensure that these programs are effective and accessible to all consumers.

Furthermore, the industry must also address the issue of contamination, as other materials or waste can contaminate the recycling process and reduce the quality of the aluminum produced. This requires additional investment in sorting and cleaning technologies, as well as education and awareness campaigns to encourage consumers to properly dispose of their aluminum cans.

Overall, the environmental concerns and recycling infrastructure challenges facing the aluminum can industry must be addressed in order to ensure its long-term sustainability and growth. By investing in sustainable production processes, recycling infrastructure, and education and awareness campaigns, the industry can continue to meet the demand for aluminum cans while also promoting environmental responsibility and sustainability.

Fluctuations in raw material prices

The aluminum can industry is facing significant challenges due to fluctuations in raw material prices. The price of aluminum is subject to change based on global market conditions, and this can have a direct impact on the cost of producing aluminum cans. In recent years, the price of aluminum has been on the rise, which has led to increased costs for manufacturers.

One of the main reasons for the price increase is the growing demand for aluminum in various industries, including automotive, construction, and packaging. This increased demand has led to a shortage of aluminum, which has driven up prices. Additionally, the COVID-19 pandemic has disrupted supply chains and further contributed to the price volatility.

These fluctuations in raw material prices can have a significant impact on the profitability of aluminum can manufacturers. To mitigate these risks, some manufacturers have implemented hedging strategies to lock in prices for their raw materials. However, these strategies can be expensive and may not always be effective in protecting against price fluctuations.

Moreover, the increasing demand for sustainable and environmentally friendly packaging solutions is putting pressure on the aluminum can industry to reduce its carbon footprint. This has led to the development of new technologies and processes that are designed to minimize waste and reduce energy consumption. For example, some manufacturers are using recycled aluminum to produce their cans, which can help to reduce the environmental impact of the industry.

Overall, the fluctuations in raw material prices present a significant challenge for the aluminum can industry. However, by implementing innovative solutions and strategies, manufacturers can continue to meet the growing demand for sustainable and cost-effective packaging solutions.

Regulatory and legislative changes

As the world continues to grapple with the issue of sustainability, regulatory and legislative changes are presenting significant challenges to the aluminum can industry. These changes are aimed at reducing the environmental impact of packaging materials, and as a result, aluminum can manufacturers are facing increased pressure to adapt to these new regulations.

One of the most significant challenges facing the aluminum can industry is the push for more sustainable packaging materials. In many countries, there is a growing movement to reduce the use of single-use plastics, and this has led to an increased focus on more sustainable packaging options. While aluminum cans are generally considered to be more environmentally friendly than plastic bottles, they are not immune to these regulatory changes.

In some countries, there are now rules in place that require manufacturers to use a certain percentage of recycled materials in their packaging. This can be a significant challenge for the aluminum can industry, as it requires significant investment in new equipment and processes to ensure that recycled materials can be incorporated into the production process.

Another challenge facing the aluminum can industry is the potential for new regulations around the use of certain chemicals in packaging materials. Some chemicals used in the production of aluminum cans have been linked to environmental issues, and as a result, there is growing pressure to find alternative materials and processes.

Overall, the regulatory and legislative changes facing the aluminum can industry are significant, and they will require companies to adapt and innovate in order to remain competitive. While these changes may present challenges, they also offer opportunities for companies to differentiate themselves as environmentally responsible and sustainable.

Competition from other packaging materials

As the demand for sustainable and eco-friendly packaging solutions continues to rise, the aluminum can industry faces increasing competition from other packaging materials. Here are some of the key challenges that the industry must overcome:

- Growing popularity of alternative packaging materials: In recent years, there has been a significant increase in the use of alternative packaging materials such as glass, plastic, and paper. These materials are often perceived as being more environmentally friendly than aluminum cans, which could lead to a decline in demand for aluminum cans in the future.

- Advantages of alternative packaging materials: Some alternative packaging materials offer advantages over aluminum cans, such as lower cost, greater flexibility, and better barrier properties. For example, plastic bottles are often preferred over aluminum cans for beverages due to their lower cost and lighter weight.

- Regulatory pressure on single-use packaging: There is growing concern about the environmental impact of single-use packaging, including aluminum cans. As a result, governments and industry bodies are imposing regulations and charges on single-use packaging, which could make it more difficult for aluminum cans to compete with other packaging materials.

- Consumer preferences for recyclable packaging: Consumers are increasingly interested in sustainable and recyclable packaging solutions. While aluminum cans are highly recyclable, other packaging materials may be perceived as more sustainable due to their biodegradability or compostability.

Overall, the aluminum can industry must continue to innovate and improve its products to remain competitive in the face of these challenges. This may include developing new alloys with improved performance characteristics, reducing the environmental impact of production processes, and improving recycling rates. By doing so, the industry can continue to meet the evolving needs and preferences of consumers and remain a key player in the packaging market.

Market volatility and economic factors

The aluminum can industry is facing several challenges due to market volatility and economic factors. Some of the key factors that are affecting the industry include:

- Global trade tensions: The ongoing trade tensions between the US and China have created uncertainty in the global market, which has impacted the demand for aluminum cans.

- Fluctuating raw material prices: The price of raw materials such as aluminum, steel, and copper can fluctuate greatly due to geopolitical factors, weather conditions, and other unpredictable events. This can have a significant impact on the cost of production for aluminum can manufacturers.

- Environmental regulations: As governments around the world introduce stricter environmental regulations, manufacturers must invest in new technologies and processes to meet these standards. This can be a significant challenge for smaller companies with limited resources.

- Increasing competition: The aluminum can market is becoming increasingly competitive, with new players entering the market and established players expanding their operations. This can put pressure on prices and profit margins for manufacturers.

- Changes in consumer behavior: Consumer preferences and behavior are constantly evolving, and manufacturers must adapt to stay relevant. For example, there is a growing trend towards sustainability and eco-friendliness, which could lead to increased demand for recyclable packaging materials like aluminum.

Overall, the aluminum can industry must be prepared to adapt to these challenges and find new ways to innovate and differentiate themselves in order to succeed in the future.

Future outlook for the aluminum can market

Predictions for growth and expansion

As the world becomes increasingly conscious of sustainability and environmental issues, the demand for aluminum cans is expected to rise. With a growing preference for recyclable packaging, aluminum cans are well-positioned to meet this demand. Here are some predictions for growth and expansion in the aluminum can market:

- Increased use in the beverage industry: Aluminum cans are already the preferred packaging material for many beverages, including soft drinks, energy drinks, and beer. As the demand for these beverages continues to grow, so too will the demand for aluminum cans.

- Expansion into new markets: Aluminum cans are not limited to the beverage industry. They are also used for packaging food products, personal care items, and household products. As the popularity of aluminum cans grows, we can expect to see them used in more and more industries.

- Advancements in manufacturing technology: The manufacturing process for aluminum cans is becoming more efficient and sustainable. Advancements in technology, such as the use of recycled materials and innovative production techniques, will make it easier and more cost-effective to produce aluminum cans.

- Increased focus on sustainability: As consumers become more environmentally conscious, there will be a greater focus on sustainable packaging. Aluminum cans are already a popular choice for eco-friendly packaging, and this trend is likely to continue.

- Growth in online sales: With the rise of e-commerce, there has been a significant increase in online sales. This trend is likely to continue, and as a result, there will be a greater need for durable and convenient packaging. Aluminum cans are well-suited to this purpose, and we can expect to see them used more frequently in online sales.

Opportunities for innovation and differentiation

As the aluminum can market continues to grow and evolve, there are numerous opportunities for innovation and differentiation. One area of opportunity lies in the development of new and improved technologies for manufacturing aluminum cans. This includes advancements in materials science, as well as improvements in manufacturing processes that can increase efficiency and reduce waste.

Another opportunity for innovation and differentiation is in the design and packaging of aluminum cans. Brands and manufacturers can differentiate themselves by offering unique shapes, sizes, and designs that appeal to consumers and reflect their brand identity. In addition, there is an opportunity to explore new and innovative ways to use aluminum cans, such as incorporating them into packaging for other products or using them as a material for other consumer goods.

Furthermore, the trend towards sustainability and environmental responsibility presents a significant opportunity for innovation and differentiation in the aluminum can market. Manufacturers and brands that can demonstrate a commitment to sustainability through their use of aluminum cans, as well as through their recycling and waste reduction efforts, are likely to gain a competitive advantage in the marketplace.

Overall, the future outlook for the aluminum can market is bright, with numerous opportunities for innovation and differentiation. As the market continues to grow and evolve, it will be interesting to see how manufacturers and brands capitalize on these opportunities and differentiate themselves in the crowded marketplace.

Strategies for success in a competitive market

In a market that is becoming increasingly competitive, companies in the aluminum can industry must develop strategies to remain successful. These strategies include focusing on sustainability, innovation, and meeting changing consumer demands.

- Sustainability: As consumers become more environmentally conscious, there is a growing demand for sustainable products. Companies that prioritize sustainability in their production processes and packaging materials will be well-positioned to succeed in the future. This includes using recycled materials, reducing waste, and implementing eco-friendly production processes.

- Innovation: The aluminum can market is constantly evolving, and companies must stay ahead of the curve by investing in research and development. This includes developing new materials, manufacturing processes, and product designs that meet changing consumer demands. For example, companies may explore the use of new alloys or manufacturing techniques to improve the durability and recyclability of aluminum cans.

- Meeting changing consumer demands: Consumer preferences are evolving, and companies must adapt to meet these changing demands. This includes offering a range of sizes, shapes, and materials to cater to different tastes and preferences. Additionally, companies may explore new product formats, such as single-serve cans or resealable containers, to meet the needs of on-the-go and convenience-focused consumers.

Overall, success in the aluminum can market will require a combination of sustainability, innovation, and meeting changing consumer demands. Companies that can successfully navigate these challenges will be well-positioned for future growth and success.

The role of technology and sustainability in shaping the future of aluminum cans

Technological advancements

One of the key factors shaping the future of the aluminum can market is technological advancements. These advancements are expected to play a crucial role in enhancing the sustainability and efficiency of the industry. Some of the technological trends that are likely to impact the aluminum can market in the future include:

- Digital printing: Digital printing technology is increasingly being used in the production of aluminum cans. This technology allows for more precise and cost-effective printing, enabling companies to create more intricate designs and personalized packaging.

- Robotics and automation: The use of robotics and automation in the production process is becoming more prevalent in the aluminum can industry. This technology can improve efficiency, reduce waste, and enhance product quality.

- Recycling technologies: Advancements in recycling technologies are expected to play a significant role in the future of the aluminum can market. These technologies can help to increase the rate of recycling and reduce the environmental impact of the industry.

Sustainability

Sustainability is another critical factor that will shape the future of the aluminum can market. As consumers become more environmentally conscious, there is a growing demand for sustainable packaging solutions. The aluminum can industry is well-positioned to meet this demand, as aluminum is a highly recyclable material that can be used repeatedly without losing its properties.

To meet the growing demand for sustainable packaging, the aluminum can industry will need to focus on improving recycling rates and reducing waste. This can be achieved through initiatives such as:

- Increasing recycling rates: The industry can work to increase recycling rates by improving collection and sorting systems, as well as by raising awareness about the importance of recycling.

- Reducing waste: The industry can also work to reduce waste by implementing more efficient production processes and by using more sustainable materials in the production of aluminum cans.

Overall, the future of the aluminum can market looks bright, with technological advancements and sustainability driving growth and shaping the industry’s future direction.

FAQs

1. What is the aluminum can market forecast?

The aluminum can market is expected to continue to grow in the coming years. Factors contributing to this growth include increasing demand for packaged goods, the rise of e-commerce, and a shift towards sustainable packaging options. Additionally, the trend towards healthier beverage choices, such as sports drinks and craft beers, is driving demand for aluminum cans.

2. What does the future hold for the aluminum can market?

The future of the aluminum can market looks bright, with a projected growth rate of around 3% annually. This growth is expected to be driven by the increasing demand for packaged goods, particularly in developing countries. Additionally, the trend towards sustainable packaging is expected to continue, with aluminum cans being a popular eco-friendly option. The rise of e-commerce is also expected to boost demand for aluminum cans, as more and more consumers turn to online shopping.

3. How is the aluminum can market changing?

The aluminum can market is undergoing a number of changes, including a shift towards sustainable packaging options and a trend towards healthier beverage choices. Additionally, the rise of e-commerce is driving demand for smaller, more convenient packaging options, such as single-serve cans. These changes are leading to increased demand for aluminum cans, particularly in the beverage industry.

4. What factors are driving demand for aluminum cans?

There are several factors driving demand for aluminum cans, including the rise of e-commerce, the trend towards sustainable packaging, and the growing demand for packaged goods. Additionally, the popularity of healthier beverage choices, such as craft beers and sports drinks, is driving demand for aluminum cans. Finally, the convenience and portability of aluminum cans make them a popular choice for on-the-go consumption.

5. What are the challenges facing the aluminum can market?

The aluminum can market faces a number of challenges, including fluctuating prices for raw materials and increased competition from other packaging options. Additionally, the trend towards sustainable packaging means that aluminum can manufacturers must work to reduce their environmental impact and improve recycling rates. Finally, changes in consumer preferences and purchasing habits could impact demand for aluminum cans.